Last time we asked: What about silver plate, silver filled, vermeil, and gold filled metals and sources of metal?

I only use solid silver in my shop for cast pieces, plate and wire. The differences in cost between silver plate, silver filled, and solid sterling silver metal is, in my opinion, not sufficient to warrant using the less expensive metal. If I am using wire to make a knit chain necklace, the cost of the metal is important, but the majority of the cost is actually in the labor. Some of my less expensive bracelets and necklaces may have silver plated clasps.

Vermeil is sterling that is gold plated. This term is rarely used outside of the United States. I use vermeil, gold filled, and gold plated clasps for necklaces and bracelets. Vermeil is the same thing as silver gilt or gilt silver which was a very common period technique. Medieval people often could not afford solid gold items either. Gilt bronze was often used, especially for large items, like bowls and reliquaries.

English: Reliquary from Limoges, France, c. 1280-1290, champlevé on gilded copper, Honolulu Academy of Arts (Photo credit: Wikipedia)

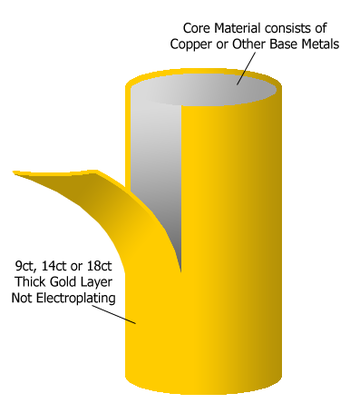

With the price of gold over a thousand dollars an ounce, solid gold is too expensive for your average customer. Gold Filled wire allows me to create affordable “gold” knit chain necklaces. Filled metal has a physically bonded layer of precious metal that is much thicker than plating.

And what about sources of metal? Any reputable metal distributor in the USA will be able to give you the actual metal content of an alloy. This is important for a number of reasons. The lead laws are one, but knowing the metal content of my supplies can be very important to my customers. Metal allergies are not that uncommon. By keeping an alloy list in my shop I can easily answer people’s questions about whether they can wear something or not. Most people will turn green from any copper alloy, I know that I certainly do, but some folks get serious contact dermatitis from nickel and other metals.

The vast majority (about 95%) of my metals come from a green US company that guarantees the metal content of their alloys. This is a serious benefit to me when I am developing new products. Each metal has very specific attributes. How much can it stretch or bend before it cracks? If I draw the wire down, will it become a lot harder and springier, or just a little.

I know people who enjoy making their own alloys, and the best of them have considerable knowledge in metallurgy. Knowing what is in the metals that you are alloying is critical. Using random bits of metal can create unanticipated issues, including lead content. I often wonder, when I see the prices of some of the items coming out of the former Soviet bloc countries, just what the metal content is. When a cast piece is selling for less than my cost to produce it, it makes me wonder. I think I will stay with guaranteed alloys from US companies!