This is the third in my series of blogs about understanding wire. If you will remember, the three basic things that you need to understand about wire are:

1. What the wire is made of.

2. How hard the wire is.

3. What gauge the wire is.

Today we are discussing wire gauges. So what exactly is a wire gauge? It is simply a unit of measure that tells us how large the wire is. It is based on the diameter of a cross-section of the wire.

There is more than one gauge scale that is used to describe the size of wire. And which scale you use is determined by where you live and what type of wire you are dealing with. In the United States and Canada the common wire gauge system that is used for measuring the type of wire that jewelers usually use is the American Wire Gauge, most often known as Brown & Sharp (B&S). It was developed in about 1855 in England by Messrs. Brown & Sharpe. The British Standard System was adopted in England in 1986. It uses a measurement system that is based on the metric system.

What is important to the artist is knowing which system of gauges is being used and what size the wire is. Obviously, if you are buying the wire in person you can simply look at it and decide which size of wire to purchase, but if you are purchasing wire online, sending someone else to buy the wire for you, or trying to duplicate a piece of wire work exactly, knowing the correct wire gauge is important. I have included a copy of the actual measurements that are associated with the B&S system. If you are working with any other gauge system or with specialty wires (iron, steel, electrical) you will need to determine what the actual measurements for that system are.

The first thing that you should notice about this system is that the larger the gauge number, the smaller the wire. The second unusual thing is that only even numbers are used. I have seen companies use odd numbered gauge sizes, but this is usually only done with the larger sized wires.

If your brain is saying “this whole thing is meaningless to me, it is just a bunch of numbers” then I have a couple of suggestions. The easiest thing to do is to get a ruler with metric markings on it and estimate the size of the wire that you want that way. Another solution is to create a little sample chart on a piece of poster board with actual examples of the different sizes of wire that they use most often- labeled. Still anoither solution is to purchase a wire gauge.

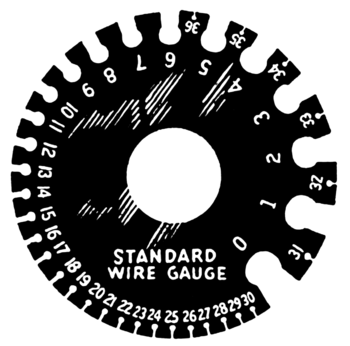

This is what a wire gauge looks like. It is a flat round piece of metal with little notches on the edge that show the actual size of the wires. It can be used to physically measure a piece of wire to determine what the gauge of the wire is, and it can also act as a visual reminder of the size of the different gauges of wire.

I hope that this brief article makes it easier for you to find the correct gauge of wire for your project!