Last time I promised to talk about Plating and Filled Metal

Plating with precious metal has been around for a very long time. Theophilus, in his book “On Divers Arts”, published in 1122, describes how to gild a surface, First you mill together mercury and gold, and then apply it to a metal surface and drive off the mercury to create a gilded surface. He notes “Be very careful that you do not mill or apply gilding when you are hungry, because the fumes of mercury are very dangerous to an empty stomach and give rise to various sicknesses…” And I should mention that the milling process is expected to take three or four hours. Fortunately today there are considerably less toxic plating techniques available, involving electricity and chemical solutions. Until fairly recently almost all precious metal plating solutions contained cyanide, but now non-cyanide plating solutions are available for the shop jeweler. Base metals can be plated with silver or gold, both with the same intention, to make a less expensive metal appear to be a more valuable. Plated pieces should be labeled as plated, and some may be stamped with the purity of precious metal that was used. The layer of precious metal is just a few molecules thick, and there is no standard to indicate how thick the precious metal is. Religious objects were often gilt during Medieval times to make them look as if they were made of solid gold.

An exception to the plating rule is Vermeil, which is Sterling silver that is plated with gold. It is an American standard. By law Vermeil has no less than 2.5 microns of karat gold (no less than 10k purity) layered over the Sterling Silver. It is usually stamped Vermeil and may include a purity stamp for the gold. Vermeil is 50 times heavier than standard gold plating.

An exception to the plating rule is Vermeil, which is Sterling silver that is plated with gold. It is an American standard. By law Vermeil has no less than 2.5 microns of karat gold (no less than 10k purity) layered over the Sterling Silver. It is usually stamped Vermeil and may include a purity stamp for the gold. Vermeil is 50 times heavier than standard gold plating.

Beware of “Dutch Gold”. It is not real gold, but rather an alloy of copper and zinc, and is usually sold in leaf form. It is sometimes used to “gild” jewelry and other objects. It can be very beautiful, but it is NOT gold.

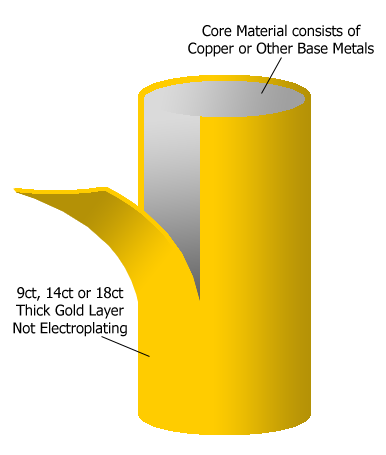

Filled Metal is made using a different technique than plating. Filled metal has a physically bonded layer of precious metal that is much thicker than plating. It is attached through a combination of heat and pressure to a base metal core. When purchasing metal stock from a supplier the metal will be listed according to the purity of the gold or silver. For instance 14/20 or 12/20 for gold means 14K or 12K. The ” /20″ part refers to the ratio of karat gold to core by weight, which is 5%. That means the precious metal is 5% of the overall weight of the metal. Different suppliers use different purities of gold.

Silver filled has a different annotation system. My supplier lists it as either 1/10 or 1/20, which means a ratio by weight of 5% and 10% respectively; 5% or 10% of the total weight of the metal is silver. I do not use silver filled materials in my shop. I feel that the difference in price is not worth it. But gold-filled materials can allow the customer to have the look of real gold in a product for a fraction of the cost of solid gold.

Next Time: Consequences